Project Results:

ABIS or Aquatic Biological Integrated System (also known as the Floating Green Filter) is an innovative biotechnology energy and chemical free wastewater treatment system developed by Agua Inc. Agua Kenya’s case for a pilot project in Kenya revolved around using ABISs to reclaim water from wastewater effluent, create green spaces, create local employment and empower Kenyans to handle their wastewater in a sustainable way that brings resources and value to people regardless of where their existing abilities and resources.

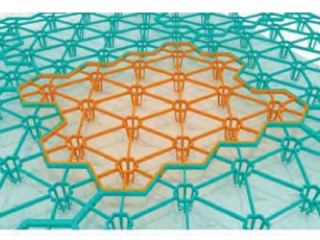

The ABIS works by excavating lagoons and directing wastewater to them. This wastewater will then go through a small screening system to eliminate solid materials (plastics etc) and fats and finally into the lagoons. The system will be installed on the new ponds using the agua floatation matrix and specially bred macrophytes. These plants when floated on water will passively aerate wastewater creating a perfect ecosystem for bacteria to thrive. This technology enables these plants to float on water and in this manner water can be purified in a completely sustainable way. Through this, wastewater treatment is connected with the sectors of agriculture, energy, education and industry – ultimately creating a closed-loop waste solution.

Through this pilot project, Aqua Inc. has helped Agua Kenya to identify and characterize over 10 plant species in Kenya towards the objective of successfully implementing and scaling ABIS in the region and developing it further and specifically for this region. Through Via Water grant funding and support from other partners outlined, Agua Kenya now has 2 pilot projects, using different plant species, up and running from the Via Water funded component with spin off projects underway as well.

Key Results

- 10 plant species in Kenya identified & characterized

- 2 pilot projects with different plant species running in Kenya

- Knowledge and technology sharing from Agua Inc. to Agua Kenya, and the development of an in-country proof of concept for ABIS

- Institutional foundation developed and capacity building for Agua Kenya

Tips for the future

- Idea to develop a mentor system to deal with both for technical and project issues that emerge

Potential for growth

With the pilots running, the foundation has been laid to help Agua Kenya to build capacity to design and prepare projects.

Project partners

Majani Matatu, Elatt, Armstrong & Duncan, International Hotel & Tourism Institute, Agua Inc, Vetlab Sports Club, Kenyatta University

Period

July 2017 - November 2018

Location

Nairobi, KenyaLast project updates

Background

Water scarcity affects 1 in 3 people all over the world and with determined industrial development as well as the continually increasing population, a delicate situation for water resources has been created. Increasingly, urban homes and industries impose an unsustainable rate of consumption, resulting in increasing pressure on a finite resource, clean water. Kenya is a water scarce country where most municipal councils are unable to supply their population with sufficient water. With the current population of about 43 million (Kenya National Bureau of Statistic) and the prevailing birth rate of about 4% per year, water scarcity will get worse over time. A significant amount of urban and industrial waste is dumped into the environment without the appropriate treatment and to compound this problem, the lack of resources available for maintaining treatment installations is a real limitation that makes accessing or reusing water very difficult. The high cost of running conventional treatment systems results in too much contamination being dumped in the rivers, in the sea and sadly also used in peri- urban and urban irrigation. Water availability is expected to decrease in many regions. Yet future global agricultural water consumption alone (including both rain-fed and irrigated agriculture) is estimated to increase by ~19% by 2050, and will be even greater in the absence of any technological progress or policy intervention. Current trends show that water withdrawals are expected to increase by at least 25% in developing countries (UNEP, 2007).

While agriculture continues to use at least 70% (up to 90% in some fast-growing economies) of water resources globally, other economic sectors will continue to compete for water resources, and some intensely, without an explicit mechanism for allocation decision-making.

Investment in safe wastewater collection and treatment, including industrial effluents, can remove a potential brake on economic activity. It has been estimated that water pollution in South Africa costs the country 1% of its annual national income (Pegram and Schreiner, 2010). The principal benefits of wastewater treatment are avoidance of the costs of pollution and the use of contaminated water by downstream users, such as other municipalities, industries, farmers and the tourist industry. In serious cases, the pollution of water bodies has caused industries to be closed down and relocated at great cost.

At Agua we are driven by the enormous nature of this problem against the backdrop of a poverty of solutions available at the moment. We believe that we can resolve many of these issues within our lifetime using innovative and locally relevant solutions for managing wastewater. Effective wastewater treatment solutions offer the opportunity to eliminate a waste product that is an economic, environmental and social burden, tackle water scarcity issues and ideally create some value from it by creating valuable resources. Agua Kenya has developed a solution that can revolutionize the management and perception of wastewater in the region. Our organization has endeavored to introduce a sustainable solution to these challenges, namely The “Floating Green Filter” (FGF) System. This technology will not only purify sewage/waste water in a completely sustainable and environmentally friendly manner, but can also clean polluted water sources like rivers and lakes to provide safe drinking water. The system is an efficient, stand-alone system that can also be incorporated into existing treatment systems to make drastic reductions in in energy consumption and operational costs.

Project Plan

1. Three lagoons will be excavated for the treatment of wastewater.

The lagoons will be placed in series for progressive treatment

For this design we will have 3 ponds in parallel surface area (200m2, 200m2 and 200m2 (100m2 FGF + 100m2 electrocarbon filter) respectively.

For this design we will have 3 ponds in parallel depth (3.5m, 2m and 1.5m respectively)

Volume per pond (in m3) 3 ponds in parallel (700m3, 400m3 and 300m3 respectively)

Mean retention time is 14 days.

2. The seedlings will go into preparation for transfer to the lagoons (1 month)

3. Wastewater will then be re-directed into the new lagoons

4. The seedlings will be transferred to floatation structures and floated on to the lagoon where purification will naturally begin occur.

5. The system will reduce odors associated with wastewater treatment.

6. The system will reduce organic sludge associated with wastewater treatment.

7. Within 4 – 6 months after floatation of the seedlings, the system will have reached maturity and be purifying the wastewater to re-useable standards.

8. We will then be able to measure and quantify FGF effectiveness and benchmark it against current systems.

9. This pilot will act as a showcase and an on field research laboratory for the university.

Target group

• Property developers (those who are not attached to sewer systems, are interested in water reuse and have space available)

• Hotels and lodges (this system can contribute towards green/eco ratings and act as a point of attraction)

• Schools and universities (as an option for water reclamation for reuse and as part of a sanitation solution)

• Factories and Food producers (as a cost cutting option for water reuse e.g. in construction, cooling boilers etc., meeting environmental discharge standards)

• Government, municipalities as new systems, retrofits for upgrading, retrofits as cost saving measures.

• Environmental restoration measures in contaminated water bodies.

Overview of Goals

This project will allow us to implement a system which will showcase this FGF technology to stakeholders, allow for further research and provide opportunities for training, innovation and up-scaling of the system. We will increase the capability of stakeholders to successfully apply treatment of wastewater, and for production and analysis of renewable resources from plants and related by-products.

The adaptation of this technology will transform water management in Kenya by providing a viable and sustainable method for recycling the various volumes of wastewater being produced. This will reduce pressure on fresh water sources and drastically reduce pollution.